All about Felting Needles

Ancient Origins ... to Modern Art

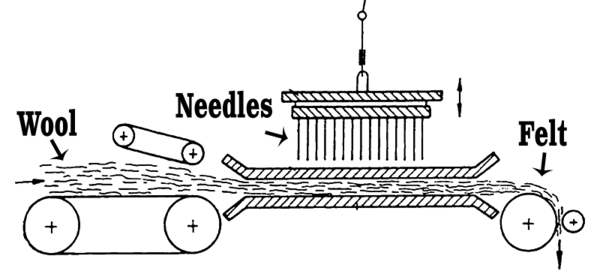

Although wool felt isn't the oldest known textile (weaving with plant fibers is quite a bit older), it does date back to around 7,000 years ago (5000-4000 BC). Wool felt is created through heat, friction, and perhaps some pH shifting liquid. The small scales in the wool act like zip-ties: letting the wool slide one direction but not the other, slowly creating a solid mesh of wool. If you've ever accidentally shrunk a nice sweater in the wash, you've made felt! Until the 1800s, felt was primarily made using a wet technique. The industrial revolution created a demand for MORE and FASTER and CHEAPER ways to make felt. Manufacturers started experimenting with other ways to convince the wool fibers to become entangled. The first Needle Punch felting machine was invented around 1866 by the Bi-Water Company of Leeds. This type of machine uses a bed of needles to punch through a wool batt, forcing the wool to entangle.

These needle felting machines never really gained popularity, remaining a niche market until the 1950s when they began to be used with recycled fabrics. Fast forward to the home of David & Eleanor Stanwood in the 1980s. They had purchased a small, sampling needle punch machine and were using it to make scarves and fanciful batts. David had the idea of taking a single needle from the machine and using it to create three dimensional objects. They shared their new-found technique with fellow artists and a new art-form was born!

Today there are thousands of needle felt artists all over the world. It's a simple hobby to get started in, all you need are some felting needles, wool, and a bit of time to stab it into shape!

Types of Felting Needles

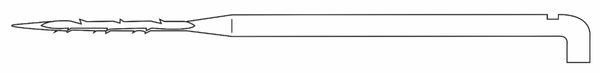

Felting Needles are (mostly) all designed to fit into large industrial machines that produce vast sheets of felt. Fiber artists have re-purposed them to use for making needle felted art but their origins are apparent in their strange design. The barbed end grabs the wool strands as it moves through and forces them to entangle just in that spot. After thousands of such stabs, the wool can become firm and take whatever shape or design the artists has chosen.

There are two main things to look at when choosing a felting needle: Gauge and Blade Shape.

The gauge is a measure of how many needles you could fit into a square inch, so a thicker needle will have a smaller number and a thinner needle will have a larger number. We carry coarse (32 gauge) to extra fine (42 gauge) needles.

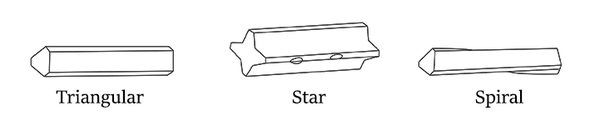

The more complicated choice is the blade shape. There are a ton of choices! The standard (and what you'll get if nothing else is specified) is the triangular blade. This gives you three, straight edges that are covered with barbs. The star point has four edges and is great for faster felting (more barbs!). A twisted or spiral blade is a regular needle where the blade has been twisted, rearranging the barbs so that they are no longer all in a row, but dispersed around the needle creating a smoother felted finish.

The outlier is the Reverse Barb needle that has its barbs turned around! Instead of creating felt when it is stabbed INTO the wool, it felts when it is pulled out. These needles can be used to create a furry surface by pulling a soft interior to the outside. They can also be used to attach stubborn pieces to each other.

Felting Needles in their original use

A single felting needle

Types of needle shafts